SHEET METAL SURFACE TREATMENT

At Spartherm, we provide comprehensive metal processing services, which is why we offer our customers various methods of sheet metal surface treatment.

Sheet metal surface treatment is a technological process aimed at improving the quality and aesthetics of metal material while extending the durability of products.

Our services are used in many industries, from automotive to heavy industry.

- Thanks to this process, sheets not only gain a better appearance but also increased resistance to corrosion and damage.

- Depending on the material specification and the component’s intended use, we tailor the surface treatment method to the individual requirements of the customer, ensuring optimal mechanical and aesthetic properties of the final product.

Our customers can benefit from sheet metal surface treatment methods such as:

- Surface grinding – is performed on our Kuhlmeyer dual-belt grinding machines. By utilizing both manual and automatic technologies, we can precisely process sheets up to 3000 mm in width (in automatic mode, up to 2800 mm) and 1000 mm in length, with the capability to handle longer elements with thicker sheets. During surface grinding, the final products achieve precise dimensions, shapes, and a smooth surface finish.

- Deburring – We specialize in deburring, removing oxide after thermal cutting, and edge rounding with surface cleaning on our COSTA wide-belt machine with a processing width of 1350 mm for materials up to 160 mm thick/height. This process allows us to achieve safe and aesthetically pleasing products.

- Cold working – Through deformation without exceeding the material’s recrystallization limit, which can only be subjected to such processing. This includes grinding, rolling, stamping, or bending.

- Hot working – Shaping by subjecting the material to high temperatures, which changes its density and improves its structure. The advantage of such processing is improving the steel’s grain and eliminating microstructure defects.

At Spartherm Strzelce Krajeńskie we also offer our customers:

- removal of oxides after thermal cutting, edge bending and cleaning of sheet metal surfaces;

- straightening and stress relief, bending of sheet metal;

- guillotine cutting and sawing;

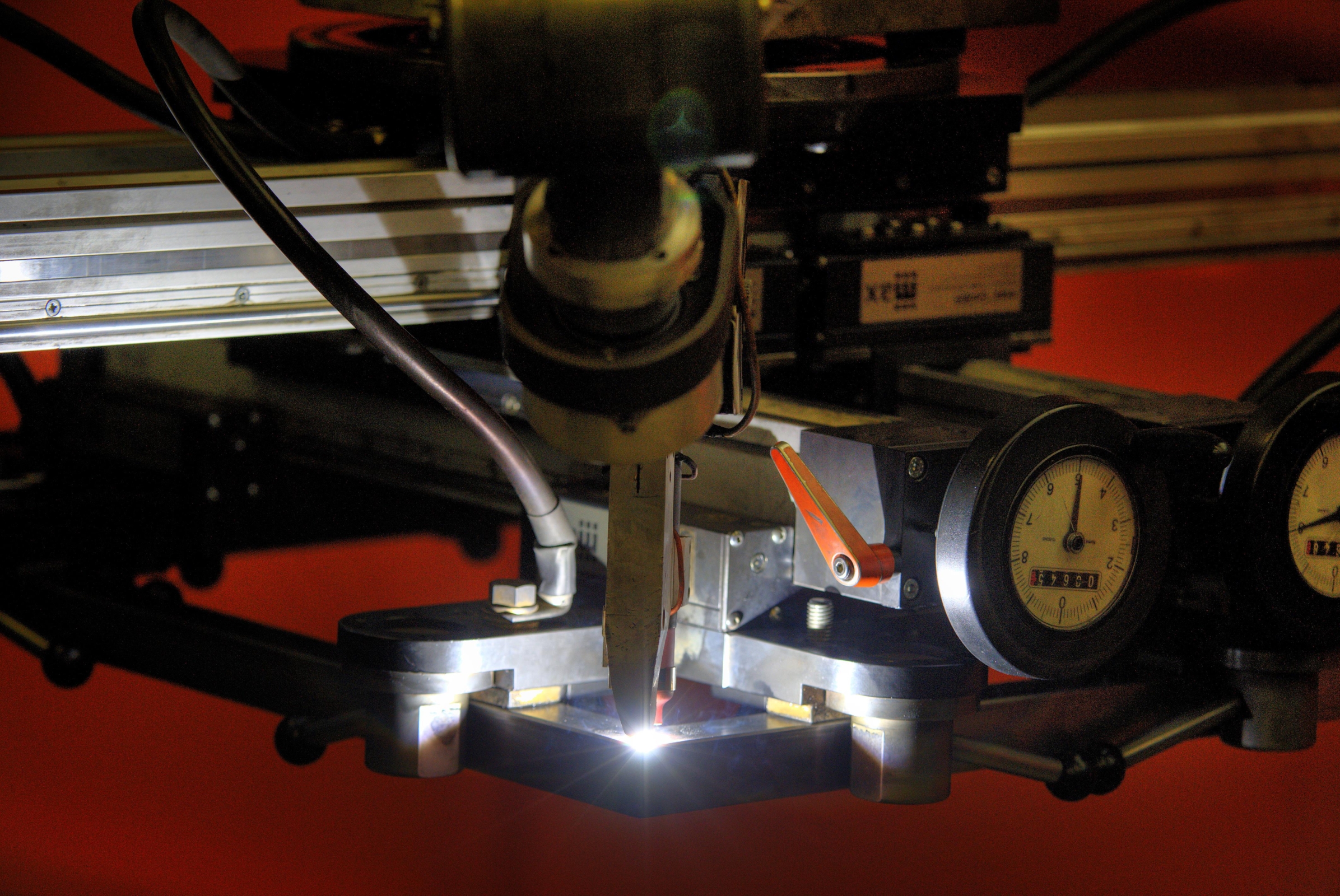

- plasma, TIG, IG, MAG, conventional welding;

- milling, CNC turning;

- hardening, shot blasting;

- deburring, rolling;

- vibroabrasive machining,

- engraving.

Your vision will become a reality with the help of our experienced team.

We are ready for new challenges!

You need implementation

individual order?

Contact us, we will be happy to undertake a non-standard project. We have the experience and creativity to meet even the most sophisticated expectations. Together we will create a unique metal processing solution that will perfectly suit your needs.